Today's HoursThursday 8:30AM - 5:00PM

Today's HoursThursday 8:30AM - 5:00PM

| Monday | 8:30AM - 5:00PM |

| Tuesday | 8:30AM - 5:00PM |

| Wednesday | 8:30AM - 5:00PM |

| Thursday | 8:30AM - 5:00PM |

| friday | 8:30AM - 5:00PM |

| Saturday | 8:30AM - noon |

| Sunday | Closed |

Krone

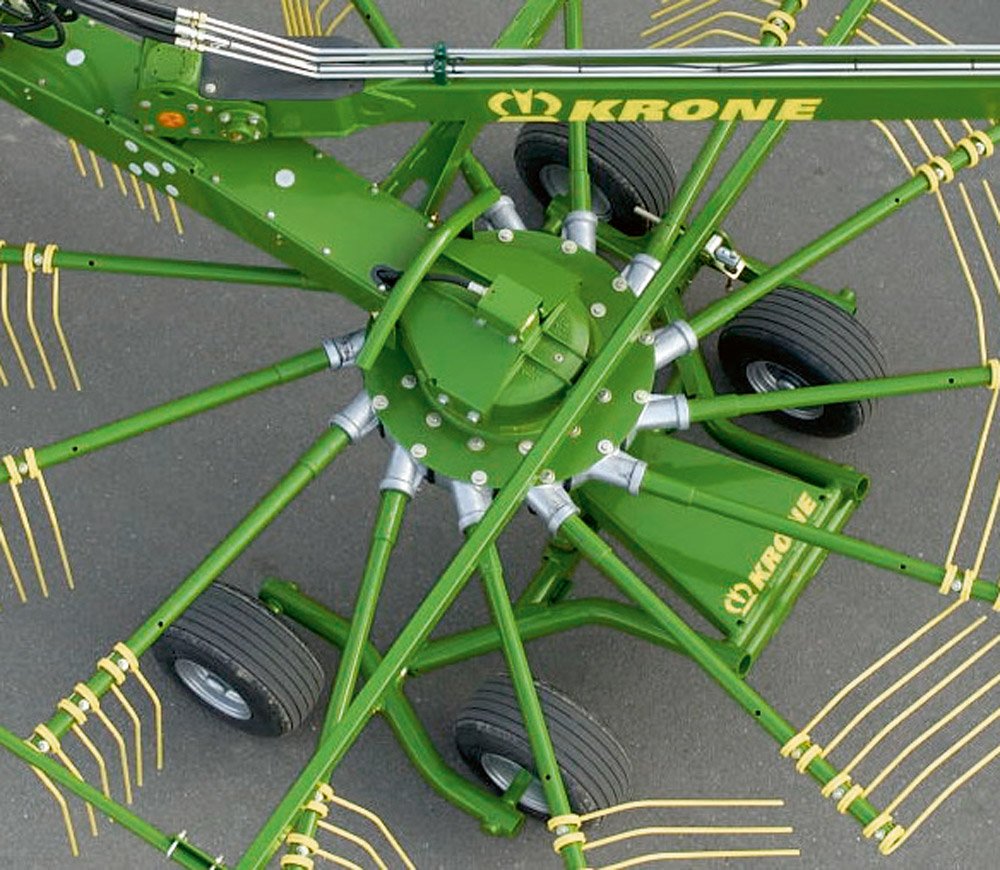

Krone Twin Rotor Side Delivery Rakes

|

|

|

Safe attachment: The drawbar – floating drawbar or linkage drawbar – is height-adjustable and the hitch ring is controlled by a parallel linkage. The hydraulic ram on the drawbar maintains the leading rotor parallel to the ground as it is lifted and lowered. |

No need to leave the cab: The rear rotor features hydraulic crop deflector control for convenient adjustment from the tractor seat. The curtain retracts hydraulically into transport position. |

Tandem axles: A wide wheelbase with 18" wheels provides excellent contouring. The leading wheels run far on the outside to provide optimum stability in sloping terrain. The working height is adjusted via these pin setting systems. |

Forming one single windrow: Raking 6.20 m (20'4") into one windrow |

Forming two windrows: Raking 6.80 m (22'4") into two windrows |

Forming double windrows: Raking 12.40 m (40'8") into one double windrow |

| Single-windrow presentation: The Swadro TS models can be adapted to the crop conditions and the intake capacity of the following harvester. Single windrows are ideal in low-yielding crops and when using balers or forage wagons. The leading rotor spins faster than the rear unit, which eliminates roping. |

| Double-windrow presentation: Raking up two separate windrows in up and down operation, Swadro TS delivers a maximum work width of up to 15 m (49'3"). Double windrowing is a very effective method to fully exploit the intake capacities of powerful harvest machines. |

| Producing two windrows with TS Twin: Swadro TS Twin has telescoping arms as standard. An optional crop deflector is available to complement the dual windrow presenting specification |

| Consistent ends: A hydraulic sequence control moves the leading rotor first and then the rear rotor into headland position. The hydraulic valves that are required to implement sequence control are controlled mechanically via a robust shift gate. Operators can set the delay between raising the front and rear arms. |

| All Swadro TS and TS Twin models have a ball bearing that links the two-point headstock and the chassis. A steering rod controls the articulated steering when the machine is travelling through curves, which gives the rake outstanding agility and allows it to enter awkward areas without shunting. No crop is left behind. |

Convenient transport height: The machine folds to a transport height of less than 4 m (13'2"), with arms moving up hydraulically and the curtain on the side lowering automatically. Convenient transport height: The machine folds to a transport height of less than 4 m (13'2"), with arms moving up hydraulically and the curtain on the side lowering automatically. |

|

Stable running and tidy windrowing

|

Tine arms and tines: The tine arms are thick-walled and large in diameter. 10.5 mm (0.4") double tines that wind around the arms in three massive spring coils offering outstanding flexibility and longevity. Each tine arm carries four double tines. Tine arms and tines: The tine arms are thick-walled and large in diameter. 10.5 mm (0.4") double tines that wind around the arms in three massive spring coils offering outstanding flexibility and longevity. Each tine arm carries four double tines. |

| Each tine arm is easily removed: Simply undo two bolts to remove the entire arm complete with bearing and roller. |

Sturdy foldback mechanism: Gap-free and hard-wearing functionality comes from a holder that is made from hardened steel and has a pivoting joint that is loaded by a Belleville spring on the models with multiple rotors. Sturdy foldback mechanism: Gap-free and hard-wearing functionality comes from a holder that is made from hardened steel and has a pivoting joint that is loaded by a Belleville spring on the models with multiple rotors. |

|

Clean windrows, better feed

|

| Setting the tines to an optimum position: The special Lift tines perform better, because their ends maintain a steep angle even in heavy crop and lift it more easily, which leads to more uniform windrows. As a result, the machine can work at a faster pace and still deliver consistently well shaped windrows. |

| No crop contamination: Thanks to their excellent performance, the Lift tines can work at a greater ground clearance than traditional tines. And thus reduce the risk of crop contamination as well as tine wear. |

|

Great stability and excellent tracking

|

| Wide track width and quiet running: It is the extra wide tracking width of the running gear that absorbs the forces that are generated by the rotors and keeps them level and stable in undulating terrain. |

|

Great flexibility and cleanest rakes

|

| The cardanic rotor suspension: The rotors pivot in and across the direction of travel to give optimum adaptation to undulating ground. A cardanic joint on the arm with two elongated holes prevents the tines from being pressed into the ground or from being left suspended in the air, thereby avoiding crop contamination as well as throwing the grass about. |

| The central suspension: The rotors suspend centrally across the direction of travel which allows them to produce consistent and high-quality windrows. The special suspension ensures they always stay level as they lift and lower on the headland. In addition, the machine’s weight is distributed uniformly on all wheels of the running gear as it travels down the field. |

|

| Permanently lubricated and maintenance-free. The enclosed bevel gearboxes and the tine arm rollers are permanently lubricated for optimum care and attention. So, operators need not bother to lube a single component on the rotor. |

| Boosting the productivity of the entire harvest chain is no problem for KRONE Swadro. The steep cam track is made from hard-wearing materials and provides precision guidance for the tines. A small track diameter in combination with massive cams make for quiet running, reduce wear and lead to well-shaped swaths. DuraMax cam track – maximum efficiency and maintenance-free components. Swadro is fun to use. |

Tel:

Tel:  22 Callaghan Road, Lindsay, ON K9V 4R4

22 Callaghan Road, Lindsay, ON K9V 4R4

The flexible side delivery rake

The flexible side delivery rake