Today's HoursMonday 8:30AM - 5:00PM

Today's HoursMonday 8:30AM - 5:00PM

| Monday | 8:30AM - 5:00PM |

| Tuesday | 8:30AM - 5:00PM |

| Wednesday | 8:30AM - 5:00PM |

| Thursday | 8:30AM - 5:00PM |

| friday | 8:30AM - 5:00PM |

| Saturday | 8:30AM - noon |

| Sunday | Closed |

Krone

Krone Pull Type Mowers EasyCut

The trailed EasyCut disc mowers from KRONE meet a wide variety of needs and requirements which vary by country, region and harvest chain. KRONE provides an extensive product range that offers the largest choice of equipment so you can to fi nd the model and specifi cation that is customized to your individual needs and requirements, for example by opting for the conditioner with V-shaped steel tines and wide distribution hood, the CRi roller conditioner, the cross conveyor belt or the hydraulic swath boards.

- Side- or mid-mounted drawbar

- Robust and fully welded cutterbar with and massive permanently lubricated sprockets

- Quick-change blades

- SafeCut INSIDE – impact protection for each individual disc

- SmartCut – blades overlap generously for stripeless cuts

- DuoGrip – double guidance and centre-of-gravity suspension

- Optimum ground pressure control from responsive and adjustable springs

- Steel tine conditioner with steep angle V-tines

- Roller conditioner with profiled rollers for intensive conditioning

- Cross conveyor belt for variable swath sizes

- Versatile and flexible in the field

- Variable specification

- Heavy-duty build

- Delivering to farmers‘ needs

For perfect control

|

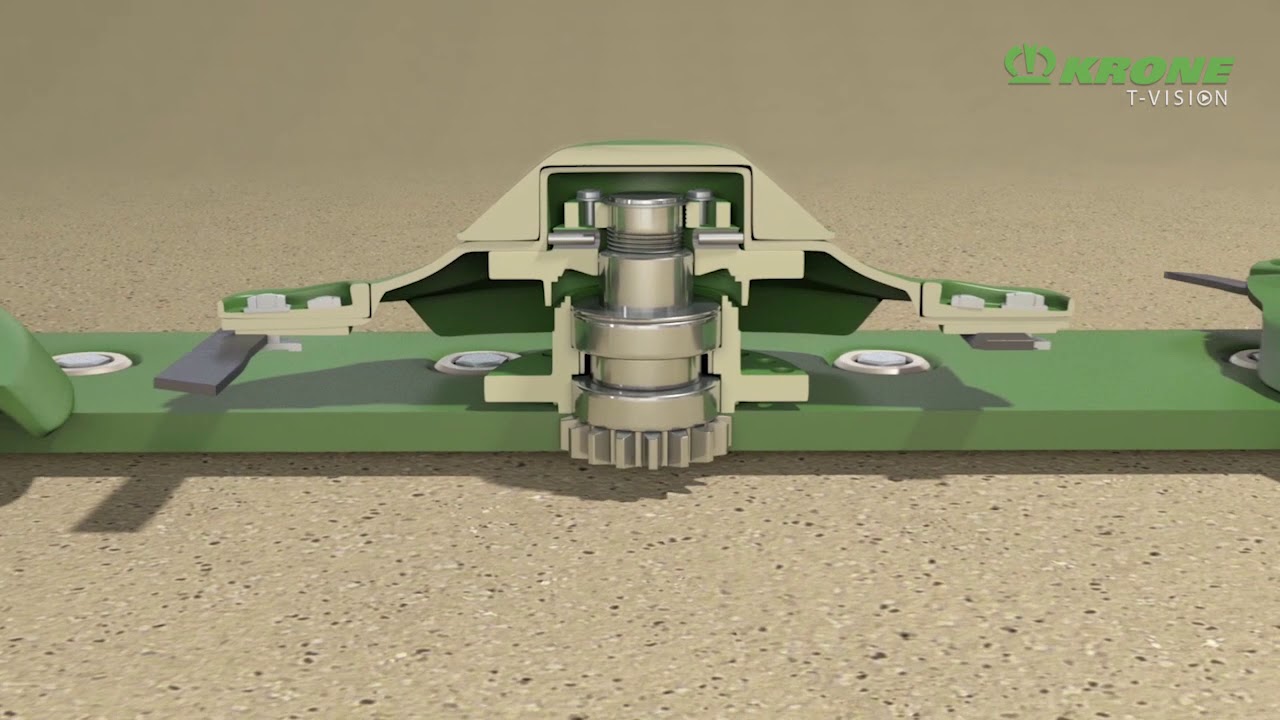

| At the heart of high-quality forage is a perfect and clean cut, which in turn is down to the specifi c design of the mower and its suspension and control system. The KRONE DuoGrip system not only suspends the mower in its centre of gravity but also provides lateral guidance, allowing the cutterbar to follow the ground contours even more accurately for more protection to the sward and high-quality forage even in diffi cult conditions. |

Quick and easy: This crank controls the cutting height. EasyCut 2801 CV and EasyCut 3201 CV may be specifi ed with an optional hydraulic ram, which tilts the mower as it crosses tramlines and runs through dips. |

An ideal system: A huge vertical travel allows the cutterbar to adapt to ground contours. Pivoting in its double frame, the mower closely follows the ground – delivering clean forage and protecting the sward. |

EasyCut TS 320 with side-mounted drawbar, without conditioner

|

| Are you looking for a powerful trailed mower without conditioner that works at a width of about 3.16 m? Then the Krone EasyCut TS 320 with DuoGrip centre-of-gravity suspension is the machine for you. This mower stands out for an extremely low power input, maximum stability as well as a superior level of specification and operator comfort. |

The trailed EasyCut TS 320 without conditioner impresses by its superior performance, very light draft and good ride qualities. Compared with a mounted mower, the trailed machine reduces the load on the tractor's rear axle and its hydraulics. As another plus, it offers a much lower transport height and hence better road safety. The transport position does not exceed 3.00 m. |

The V-shaped frame of the EasyCut TS 320 model with side-mounted drawbar is robust and compact. Its generous ground clearance makes for plenty of vertical travel. Suspended in its centre of gravity and linkage controlled, the cutterbar swings back and up through a large angle avoiding obstacles, a design that ensures clean work also in undulating fields. The cutterbar is driven by a powerful right-angle gearbox which makes for a frictional connection and is arranged behind the inner top hat. |

It takes just a minute to adjust the machine perfectly to the current conditions. The cutterbar’s ground pressure is set by tensioning the coil springs. |

Equipped with side-mounted drawbar and pivoting gearbox, the unit cuts around any bend. The two-point headstock attaches to the height-adjustable link arms – although the floating drawbar has become the preferred choice of attachment in some countries. |

The front curtain folds up to give convenient access to the discs for easy cleaning and blade replacement. |

Running inline behind the tractor during road travel, EasyCut TS 320 does not exceed the statutory 3 m transport width, gives plenty of ground clearance and is approved to 40 km/h maximum speed. This is the machine to travel quickly between sites. |

Featuring mid-mounted drawbar and conditioner

|

EasyCut 6210 CV – one machine, two conditioners: A 6.20 m (20'4") working width and a central drawbar make EasyCut 6210 CV one of the most effective trailed mowers on the market. These machines stand out for superior effi ciency, maximum stability as well as an advanced level of specifi cation and operator comfort. The CV high-capacity conditioner produces best quality forage. |

Take your pick: EasyCut 6210 CV cuts to the right or left of the tractor. The changeover is straightforward indeed. Simply swing the drawbar to the other side as you do the headland turn and match up with the previous pass without mowing in beds. The tractor is not running in standing crop so that clean and loss-free cuts are guaranteed. This way you always use the machine to potential and, in combination with a front-mounted mower, at full width capacity. In sloping fields, it allows the tractor to run always on the hillside. |

Enthused by perfection: EasyCut 6210 CV, the disc mower that delivers technology, functionality, smooth handling and ultimate convenience. This is the machine for high-power standard tractors, which has starred in contracting applications. Featuring a robust double frame, powerful conditioners, and wide tyres, this is the equipment that delivers – no matter how demanding the conditions. |

Time is money: Although high work rates are the priority for contractors, travel time is another important cost factor. EasyCut 6210 CV is a swift road machine that travels at 40 km/h (25 mph). The robust running gear with air brake system and the large-diameter wheels translate into excellent road safety and operator comfort. The large warning panels and road lights provide safety at dawn and at night. |

Turn on the spot: The swivel-head gearbox (1,000 rpm) on the two-point headstock provides the flexibility to turn through 90° and larger angles while the main driveshaft does not move, allowing drive power to flow vibration-free to the cutterbar. |

Wide work widths or narrow transport widths: It takes just a few seconds to swing the machine from work into transport position and vice versa. There is no need to leave the tractor. It does not take a sophisticated system to control the semi-mounted chassis and its hydraulic ram. A 2.99 m (9'10") transport width and 15.0/55-17 tyres ensure this high-capacity mower provides superior rides without requiring special permission for public roads. |

EasyCut TS 320 with side-mounted drawbar, without conditioner

|

| Are you looking for a powerful trailed mower without conditioner that works at a width of about 3.16 m? Then the Krone EasyCut TS 320 with DuoGrip centre-of-gravity suspension is the machine for you. This mower stands out for an extremely low power input, maximum stability as well as a superior level of specification and operator comfort. |

The trailed EasyCut TS 320 without conditioner impresses by its superior performance, very light draft and good ride qualities. Compared with a mounted mower, the trailed machine reduces the load on the tractor's rear axle and its hydraulics. As another plus, it offers a much lower transport height and hence better road safety. The transport position does not exceed 3.00 m. |

The V-shaped frame of the EasyCut TS 320 model with side-mounted drawbar is robust and compact. Its generous ground clearance makes for plenty of vertical travel. Suspended in its centre of gravity and linkage controlled, the cutterbar swings back and up through a large angle avoiding obstacles, a design that ensures clean work also in undulating fields. The cutterbar is driven by a powerful right-angle gearbox which makes for a frictional connection and is arranged behind the inner top hat. |

It takes just a minute to adjust the machine perfectly to the current conditions. The cutterbar’s ground pressure is set by tensioning the coil springs. |

Equipped with side-mounted drawbar and pivoting gearbox, the unit cuts around any bend. The two-point headstock attaches to the height-adjustable link arms – although the floating drawbar has become the preferred choice of attachment in some countries. |

The front curtain folds up to give convenient access to the discs for easy cleaning and blade replacement. |

Running inline behind the tractor during road travel, EasyCut TS 320 does not exceed the statutory 3 m transport width, gives plenty of ground clearance and is approved to 40 km/h maximum speed. This is the machine to travel quickly between sites. |

|

EasyCut Trailed Center Mower Conditioner

The EasyCut Trailed Center (TC) mower conditioner comes with the option of a 2-point hitch or drawbar and various conditioner options. These mowers can reach production of 15 -18 acres per hour, depending on model, and is the ideal mower conditioner for fields with narrow gates, due to the optional end wise transport. |

|

Perfect in every detail

|

Thorough protection: We welded curved stops between the individual skids to protect the cutterbar from damage and we also contoured the underside of these stops so no material can collect here. As a result, the material flows smoothly to the rear. |

|

Saving time and money

At KRONE, developing a machine means translating user ideas, suggestions and demands into dependable hardware. This is how we designed and developed our trailed mowers. Their unique strength and stability, the quick-changing blades, inexpensive wearing parts and above all, their superior work quality are just some of the reasons that speak for a KRONE disc mower. |

Quick and easy blade change: Quick-change blades are a must for many users and so we cut the change down to a few seconds. |

Minimum wear: With the blades being free to spin through 360° on their pins, they are hard-wearing and self-cleaning, well protected and will not foul with the blades on the neighbouring discs. |

A gripping system

|

Full-width conditioning: The CRi rollers are full-length and single-piece, which suggests uniform treatment across the full working width. Thanks to stepless adjustment of roller clearance and pressure, the system easily adjusts to the current crop yield and variety. The polyurethane coating offers lasting resistance to abrasion and wear. |

The specialist in Lucerne: Such delicate and broad-leaved crops as Lucerne are best conditioned by the interlocking KRONE CRi roller conditioner, which features two chevron profiled rotors for gentle treatment of the delicate leaves whilst crimping the stems for faster and more uniform wilting. |

250 mm (10") in diameter: The massive CRi rollers ensure a smooth and unobstructed crop flow whilst reducing tractor power. |

Frictional connections: The drive power to the roller conditioner flows directly and slip-free via gearboxes. The gears that drive the bottom roller are integrated in the cutterbar gearbox behind the left top hat. |

The specialist for quality forage

|

The high-performance KRONE CV steel conditioner with aggressive V-tines spreads the crop at the full working width. Its massive 640 mm (2'1") diameter rotor and its helical arrangement of the tines warrant a continuous crop flow, high intakes and superior conditioning. |

Cutterbar and conditioner share the same gearbox. The integral mechanical gearbox that drives the CV conditioner offers two speeds – 600 rpm and 900 rpm. |

Firm grip on the crop: Made from hardened steel and mounted at a steep angle, the V-shape steel tines give intensive treatment and powerful action. The tines pivot to break back when they hit an object whereas their restricted forward angle increases the pivot pin‘s longevity. |

Tel:

Tel:  22 Callaghan Road, Lindsay, ON K9V 4R4

22 Callaghan Road, Lindsay, ON K9V 4R4